We need them to avoid layers collapsing during the printing process if their overhang.

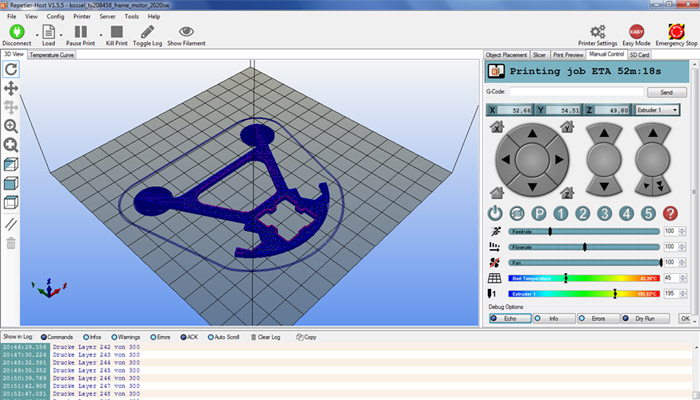

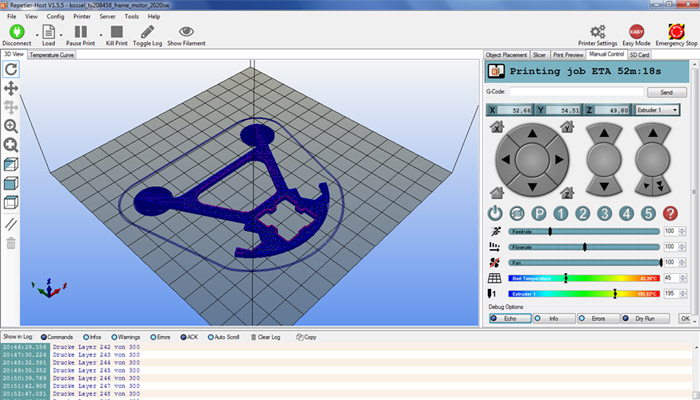

Supports: Structures made for overhangs. There are many possible patterns to distribute the material within the hollow space.  Infill: Fixes density percentage inside the object. Inner walls: The material lines that define the shell thickness. Outer wall: The material line that defines the surface of the shape. Shell: The external lines that define the shape of the object. The following are the main types of distributions: It allows you to check how the material would be distributed within. Layer preview: Once the parameters are ready, the interface lets you scroll through each layer. Model positioning controls: Same as the previous point. Visualization and camera control: Through icon bars and mouse/keyboard controls. If you are printing multiple objects, you can check how they’ll arrange. Model orientation, scale and position relative to the bed. With this, you have a graphical representation for: Here you can visualize a comparison between the object and the space provided by the printer. Printing bed plane: It represents the shape and dimensions of the real bed. Every slicer has its unique interface style, but there are common elements to consider: Slicers offer a 3D graphics area where you can visualize how the model transforms into a layered representation. There are 3 key interface sections: The graphics area, a slicing settings panel, and some general settings.

Infill: Fixes density percentage inside the object. Inner walls: The material lines that define the shell thickness. Outer wall: The material line that defines the surface of the shape. Shell: The external lines that define the shape of the object. The following are the main types of distributions: It allows you to check how the material would be distributed within. Layer preview: Once the parameters are ready, the interface lets you scroll through each layer. Model positioning controls: Same as the previous point. Visualization and camera control: Through icon bars and mouse/keyboard controls. If you are printing multiple objects, you can check how they’ll arrange. Model orientation, scale and position relative to the bed. With this, you have a graphical representation for: Here you can visualize a comparison between the object and the space provided by the printer. Printing bed plane: It represents the shape and dimensions of the real bed. Every slicer has its unique interface style, but there are common elements to consider: Slicers offer a 3D graphics area where you can visualize how the model transforms into a layered representation. There are 3 key interface sections: The graphics area, a slicing settings panel, and some general settings. SLICER SOFTWARE SOFTWARE

Depending on which software you use, there are alternative file options. Every slicer has the option to generate a gcode. Export: After checking and making sure everything is ok, you can create and save your file.Most slicers calculate an estimation for printing time and material quantity to use. Here you can preview the resulting elements and how they will be applied in real life. Slice and preview layers: With everything set, the slicer is ready to calculate and cut the part into layers.Further down in this post we’ll get deeper into it. Setup commands: Here’s the most important step for slicers.

There are also scaling and alignment options.

Arrange model: A slicer interface allows control over the position of the part and its contact with the printer bed. All slicers read STL, but other files like OBJ, 3DF and AMF are becoming more accepted every year. Import model: Once the printer data is set, you need to import the model you’ll work with. Additionally, there are more settings regarding the extruder type and the material specifications. If this isn’t correctly set from the beginning, the gcode will send commands impossible for the printer to handle. Setup printer settings: The slicer needs all the information regarding the printer’s limitations. The following are the typical steps for slicing a model. For a slicer, the 3D model and the manufacturing requirements are the input and the gcode file is the output. A gcode is a detailed command list readable by a printer to optimize everything it needs during the process.Īs you get more experienced with slicing, you’ll see there’s a set of other parameters that impact drastically the final result.Īny process must have an input and end with an output. The 3D Printer does not receive a geometric file (Commonly STL), but a gcode. We call it a “Slicer” because of its main function: dividing the model into individual material layers throughout the z-axis or “slices”. Thankfully there are software programs specifically made for this: The slicers.ģD Printing, as with any skill, is a process learned through the mastery of a tool and experience.Ī slicer tells the printer everything it needs to know to print an object in the best possible way. That is to say, there is a required process called slicing sitting between the CAD model and the physical object. 3D printing processes aren’t quite as simple as throwing a 3D model into a printer and expecting the object to magically appear.

0 kommentar(er)

0 kommentar(er)